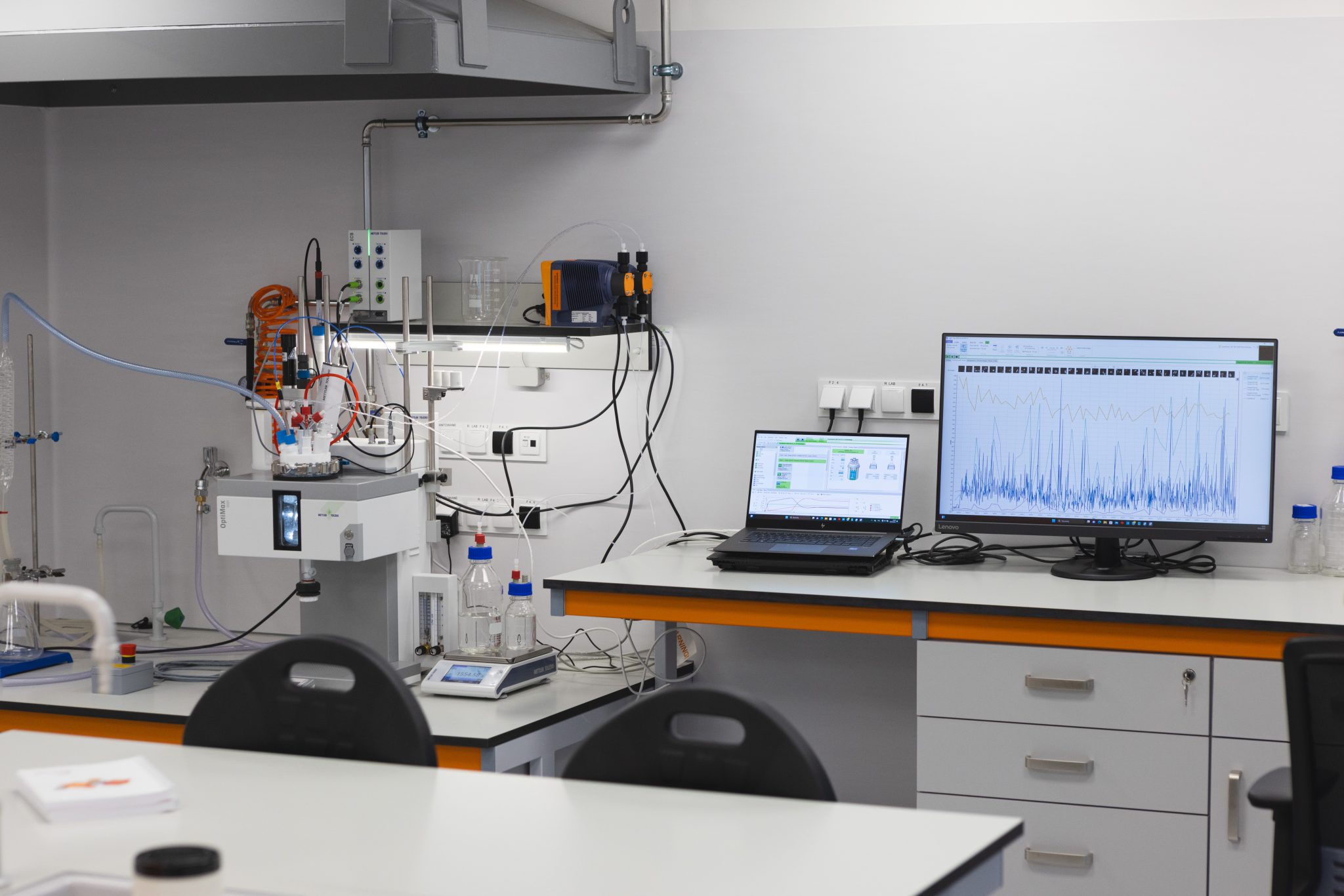

Technology Research Workroom

An invaluable asset in conducting conceptual and implementation work is a well-equipped research facility. The Technology Research Workroom is housed in specially designed spaces for precise studies. Advanced equipment enables a wide range of research and analysis, including synthesis, crystallization, distillation and calcination processes, as well as environmental simulation for long-term studies. We also conduct non-standard tests tailored to individual client needs.

Equipment:

The Workroom is equipped with a complete research station featuring the OptiMax 1001 system (including calorimetry module) and the EasyViewer 100 analyzer (METTLER TOLEDO). The innovative OptiMax chemical synthesis reactor is a platform that enables highly precise control of reaction parameters, which is crucial for optimizing production and improving process efficiency across various industries. The station allows full control over parameters within a 1000 ml reaction chamber, including temperature (from -20°C to 180°C), dosing rate, retention time and reaction kinetics, as well as continuous pH and thermal effect measurement (calorimetry).

The EasyViewer system, which includes a probe-based video microscope, enables continuous measurement of particle size and quantity, which is particularly useful in crystallization processes. Additionally, the control software allows all collected data to be used for process programming.

Given the wide range of research conducted, the Workroom is also equipped with various sample preparation and complementary analysis devices, including:

- Memmert climate chamber – allows for the simulation of environmental conditions in long-term studies of materials used in the chemical and energy industries.

- Thermconcept high-temperature furnace – enables thermal processing of samples at temperatures up to 1100°C, used primarily in mining and metallurgical research.

- Devices for physicochemical parameter analysis (pH meter, conductivity meter) and sample grinding equipment (ball mill with a sieve shaker for bulk material analysis).

- Precision dosing equipment for solid, liquid and gaseous materials.

Possible applications:

Our research finds application in various sectors, including:

- Mining and Metallurgy:

- Performance and energy efficiency studies in the chemical processing of raw materials.

- Studies on fraction separation through precipitation, filtration, and leaching, with continuous particle size measurement during processes.

- Optimization of solid particle separation and ore beneficiation processes.

- Chemical and Fertilizer Industry:

- Development of new methods for processing mineral raw materials.

- Tailor-made crystallization techniques for mineral salts.

- Optimization of drying and calcination processes in fertilizers production.

- Stability, solubility and leaching tests of fertilizer products in various environmental conditions.

- Water Management and Desalination Technologies:

- Analysis of the efficiency of ion removal methods in water treatment processes.

- Crystallization processes to reduce pollutants in water and recover pure desalination products.

- Optimization of energy parameters in membrane and thermal desalination processes.

Thanks to our wide range of capabilities, the Technology Research Workroom is prepared to conduct diverse research projects, supporting both R&D initiatives and industrial implementation analyses.

Contact:

Michał Strzelecki, Ph.D., engineer

acting Energy Technologies Department Manager

tel. +48 71 781 22 43

send e-mail:

Sikorskiego Street 2-8,

53-659 Wrocław

Karol Wojciechowski

acting Energy Technologies Department Deputy Manager

tel. +48 71 781 22 14

send e-mail:

Sikorskiego Street 2-8,

53-659 Wrocław